- Contact:Ms. Zhang

- Cel:0086-18053229518

- Mail:info@qdrunjuxiang.com

- Add:Chengma Road, Qijialing Village, Tongji New District, Jimo City, Qingdao

Talking about the maintenance of non-woven equipment

1, the first level maintenance work is carried out on the basis of routine maintenance, the key work content is lubrication, fastening and inspection of the relevant parts and cleaning.

2, secondary maintenance work to check, adjustment as the focus. Specifically, it is necessary to check the working conditions of the motor, transmission, transmission mechanism, working device, air pressure system and electrical system and make some adjustments to eliminate the faults found to ensure that the assembly and parts of the machinery have good working performance.

3, the focus is to detect, adjust, eliminate hidden trouble and balance the wear degree of each part. It is necessary to carry out diagnostic inspection and status detection on the parts that affect the performance and the parts with faults and symptoms, and then complete the work of replacement, adjustment and troubleshooting.

Through the above description, we can understand the specific details of the maintenance of non-woven equipment, maintenance work should be carried out from several aspects to ensure that our equipment can be fully maintained, so that our non-woven equipment can be used longer. If you have any doubts about the use of non-woven equipment, you can communicate with us and will give you a satisfactory answer.

Need to purchase non-woven equipment, looking for Qingdao Runjuxiang Machinery Co., LTD., thank you for your support to the company!

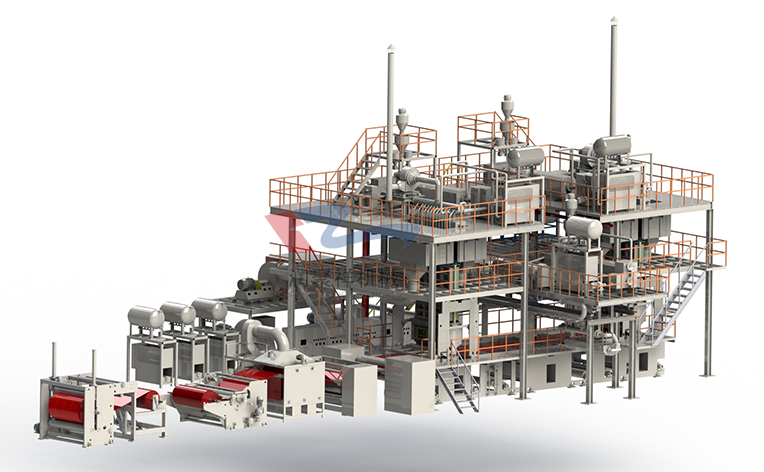

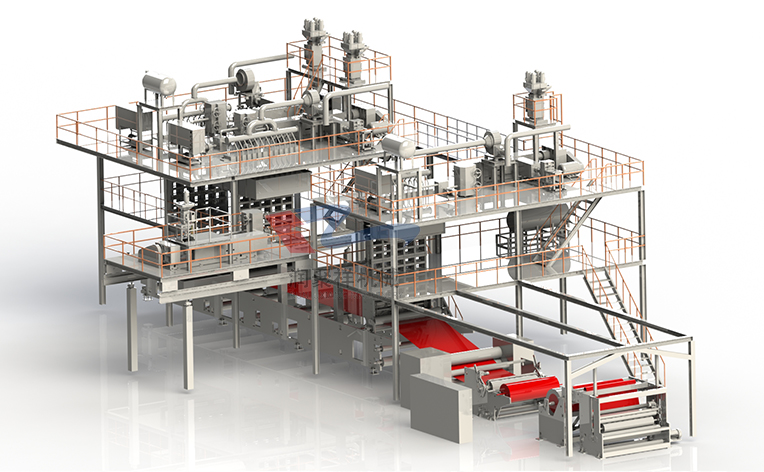

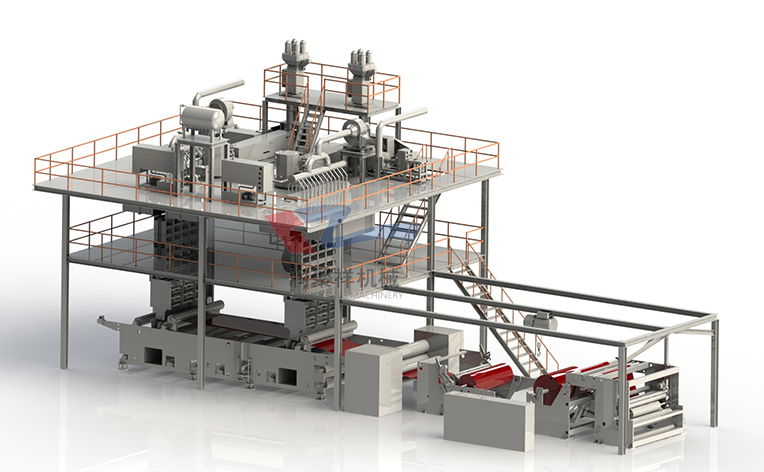

Qingdao Runjuxiang Machinery Co., Ltd. has been focusing on the production and manufacturing of spunbond and spunmelt non-woven equipment since its inception, and has been deeply engaged in this industry for more than 20 years. It has successfully designed, manufactured and installed more than 300 PP non-woven production lines in the world, and won the trust and support of many professional customers at home and abroad.

Henan Runjuxiang New Materials Co., LTD., is our company in order to achieve greater development and new investment to establish the factory, located in Nanyang, Henan Province, covers an area of 18000 square meters. In addition to non-woven equipment manufacturing, Henan Runjuxiang has independently developed and assembled a two-component production line in the factory, which intuitively displays our advanced production technology to visiting guests and strives to promote the development of two-component technology in China. Technology: Our factory introduces and digests and absorbs advanced design concepts and manufacturing technology at home and abroad, including five generations of Leifen, through years of production practice and independent innovation, our equipment technology is currently in a leading position in the country, and the stability of equipment operation has been unanimously recognized by our customers.

Cloth: The cloth weight suitable for our equipment is 8-80 grams, especially the high-speed model 8-20 grams of Eisai thin cloth, the wire fineness can be maintained below 1.8D or even 11-1.2D longitudinal and horizontal tension of the product meets or exceeds the national standard. The uniformity of the cloth produced by our equipment is very good, which is very important for the application of Eisai medical industry.

Qingdao Runjuxiang Machinery Co., Ltd. is a professional production:SMS spunbond and melt-blown non woven machinery line,Spunbond non woven machinery line,Spunbond and melt-blown non woven machinery line,SSMMS spunbond and melt-blown non woven production line,SSS spunbond non woven production line。

If you want to know more about our company information, please contact: Mr Valley 18661750769 web site: http://www.qdrunjuxiang.com

- After the Minor Snow season, Qin

- Innovation and upgrading in the

- The non-woven fabric machinery o

- The operation of China's industr

- As the chill of November intensi

- The textile industry forges new

- What are the wide application fi

- A brief overview of the operatio

- Runjuxiang is deeply engaged in

- The economic operation of China'

- About RunJuXiang

- Company Profile

- Company Culture

- Non-woven production line

- Spunbond nonwoven production line

- Two-component Bi-Co

- Spun melted nonwoven production line

- Equipment Accessories

- Meltblown nonwoven production line

- Non-woven products

- News Center

- Company News

- Show Information

- Contact Us

- Contact RunJuXiang

- Online Message