- Contact:Ms. Zhang

- Cel:0086-18053229518

- Mail:info@qdrunjuxiang.com

- Add:Chengma Road, Qijialing Village, Tongji New District, Jimo City, Qingdao

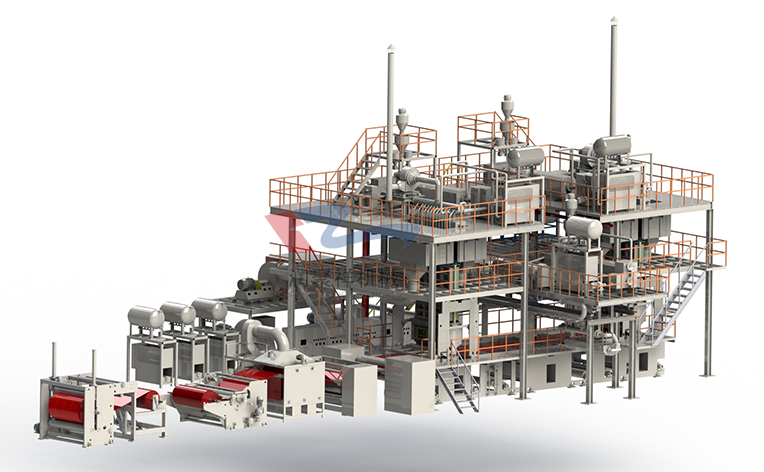

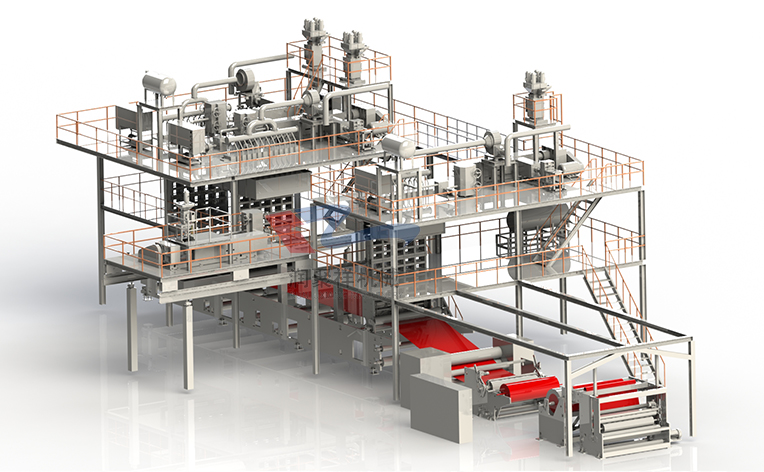

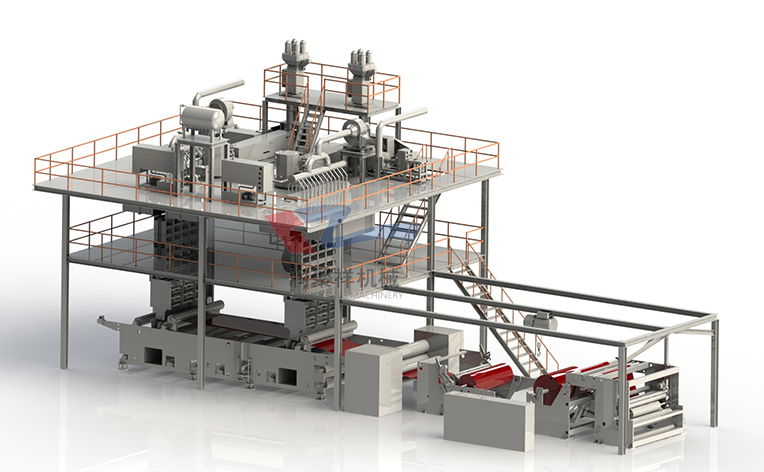

Introduction of non-woven equipment

1, non-woven machinery equipment drum part, cotton opening roller is an important part of the machine, by the simplified body, corner nails, flanges, hollow shaft and so on. The corner nails mounted on the cylinder are arranged in a spiral pattern. The raw material fed from the cotton inlet enters along the tangential direction of the beater. With the action of the rear fan, they rotate around the outer surface of the agitator. The advantage is that it extends the residence time of the raw material in the machine and increases the number of times the raw material is hit. Therefore, the release effect is good, the impurity removal efficiency is high, has become one of the remarkable characteristics of the machine. Another remarkable feature of the nonwoven equipment is the opening strength, that is, the speed of the opening roll, which has the function of online adjustment. In order to facilitate the formulation of process parameters, the open hole strength is divided into 1 ~ 10 levels, and the speed of the open hole beater is automatically converted into the speed of the open hole beater through the PLC program (480 ~ 960 R/min, the speed difference of each stage is about 48), and the operation of the frequency converter of the open hole beater is controlled, so as to realize the online adjustment function of the beater speed. Change the beater speed and stop to replace the pulley.

2, compared with non-woven machinery and equipment, its superiority is self-evident. Dust removal grille device is the main component of non-woven equipment, which is composed of dust removal rod, regulating plate, connecting rod mechanism and stepping motor. The dust-proof rod is divided into two groups, the initial installation Angle is 10 ', the maximum Angle is 40 '. The machine drives the linkage mechanism through two stepping gear motors and synchronously adjusts two sets of dust bars. The mounting Angle of the dust bar can be set to seven levels on the control panel according to raw material conditions and process requirements. The installation Angle difference between the grades is 5. Similarly, the mounting Angle of the dust bar is changed to online adjustment.

The polypropylene used in non-woven equipment is a pure linear saturated hydrocarbon polymer macromolecule without polar groups and active groups, and has high chemical stability.

The polypropylene fiber used in non-woven equipment has high crystallinity, dense structure and strong hydrophobicity, which make polypropylene provide dyeing, and dye molecules cannot or are difficult to diffuse to the room. Therefore, in order to improve the practicability and aesthetics of polypropylene non-woven fabrics, the production of color masterbatch adopts the pre-spinning dyeing method.

Qingdao Runjuxiang Machinery Co., Ltd. has a large number of professional engineers, technical backbone and a well-trained team of technicians, with strong technical force. Elite team, all-round follow-up of product production.

Qingdao Runjuxiang Machinery Co., Ltd. has established a perfect after-sales service system, eliminating the worries of customers, quick response, one-stop service, to "meet customer needs" as the goal, forge ahead, the courage to climb.

If you want to know more about our company information, please contact: Mr Valley 18661750769 web site: http://www.qdrunjuxiang.com

- After the Minor Snow season, Qin

- Innovation and upgrading in the

- The non-woven fabric machinery o

- The operation of China's industr

- As the chill of November intensi

- The textile industry forges new

- What are the wide application fi

- A brief overview of the operatio

- Runjuxiang is deeply engaged in

- The economic operation of China'

- About RunJuXiang

- Company Profile

- Company Culture

- Non-woven production line

- Spunbond nonwoven production line

- Two-component Bi-Co

- Spun melted nonwoven production line

- Equipment Accessories

- Meltblown nonwoven production line

- Non-woven products

- News Center

- Company News

- Show Information

- Contact Us

- Contact RunJuXiang

- Online Message