- Contact:Ms. Zhang

- Cel:0086-18053229518

- Mail:info@qdrunjuxiang.com

- Add:Chengma Road, Qijialing Village, Tongji New District, Jimo City, Qingdao

The specific details of the maintenance work of non-woven equipment, the maintenance work should be carried out from several aspects to ensure that our equipment can be fully maintained, so that our non-woven equipment can be used for a longer time. If you have any doubts about the use of non-woven equipment, you can communicate with us and we will give you a satisfactory answer.

1. The first-level maintenance work is carried out on the basis of routine maintenance, and the key work content is lubrication, tightening and inspection of all relevant parts and cleaning.

2. The secondary maintenance work focuses on inspection and adjustment. Specifically, check the working conditions of the motor, transmission, transmission mechanism, working device, air pressure system and electrical system and make some adjustments to eliminate the found faults to ensure that the mechanical assemblies and parts have good working performance.

3. The key is to detect, adjust, eliminate hidden troubles and balance the wear degree of various parts. It is necessary to carry out diagnostic inspection and status detection on the parts that affect the performance and the parts with faults and symptoms, and then complete the work of replacement, adjustment and troubleshooting.

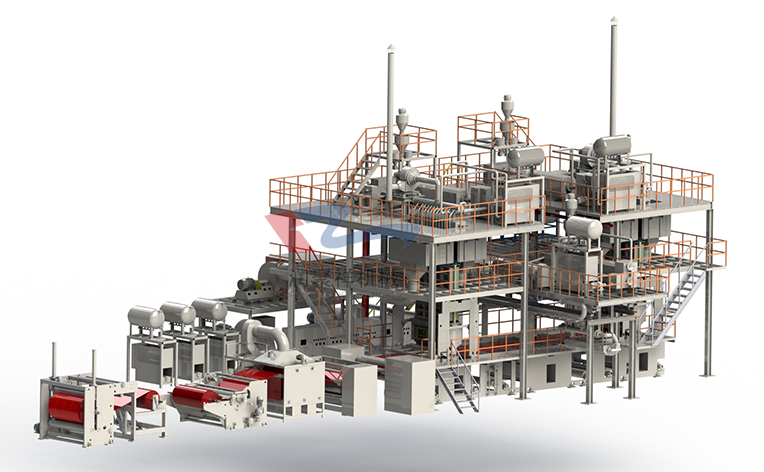

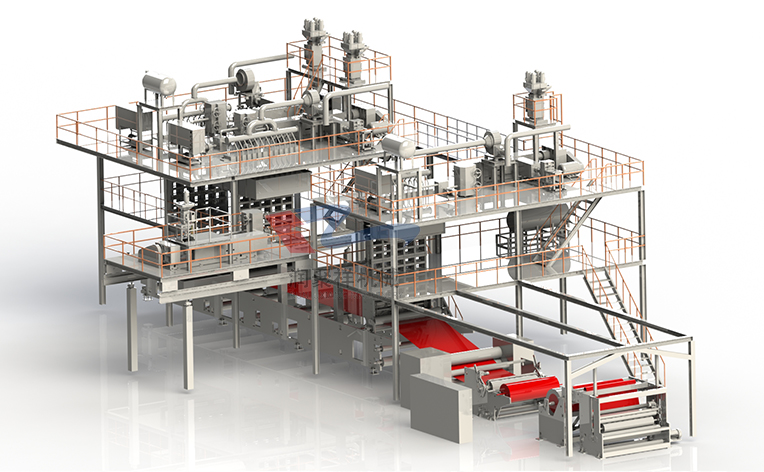

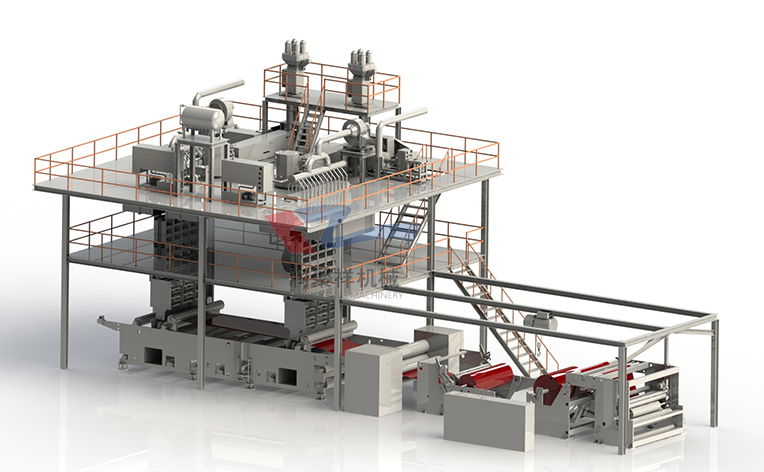

Qingdao Runjuxiang Machinery Co., Ltd. is specialized in producing non-woven equipment, non-woven production line, spunmelt non-woven production line, melt-blown non-woven production line, non-woven machinery, melt-blown non-woven equipment, etc.

If you want to know more about our company, please contact: Mr. Gu 18661750769 Website: http://www.qdrunjuxiang.com

- As the chill of November intensi

- The textile industry forges new

- What are the wide application fi

- A brief overview of the operatio

- Runjuxiang is deeply engaged in

- The economic operation of China'

- In September, the production sea

- On the eve of the "Golden Septem

- The textile market situation of

- In September, the autumn is in f

- About RunJuXiang

- Company Profile

- Company Culture

- Non-woven production line

- Spunbond nonwoven production line

- Two-component Bi-Co

- Spun melted nonwoven production line

- Equipment Accessories

- Meltblown nonwoven production line

- Non-woven products

- News Center

- Company News

- Show Information

- Contact Us

- Contact RunJuXiang

- Online Message