- Contact:Ms. Zhang

- Cel:0086-18053229518

- Mail:info@qdrunjuxiang.com

- Add:Chengma Road, Qijialing Village, Tongji New District, Jimo City, Qingdao

Spunbond nonwoven fabrics use the principle of chemical fiber spinning to lay continuous filaments into a web during the polymer spinning process. The filament web is subjected to needle punching, spunlacing, chemical bonding, hot rolling bonding Method or hot air bonding method to form a nonwoven fabric.

The web of spunbond nonwoven fabric is composed of continuous filaments, so it has good tensile strength; the linear density of the filaments constituting the nonwoven fabric can be large or small, with a wide range of changes; the web can be reinforced by various methods , So as to give products with good application performance and enhance competitiveness. Spunbond nonwoven fabrics are formed by continuous filaments laid into a mesh and directly formed into a fabric. The fiber utilization factor is high, the coverage per unit area is large, and the covering performance is good. Therefore, it can be processed into a non-woven fabric with a low areal density. Unmatched by various non-woven fabrics. Generally speaking, the spunbond nonwoven fabric has high comprehensive strength level, smooth surface, low fleece, soft hand feeling, fold resistance and abrasion resistance, good shading and breathability, good water absorption and lipophilicity, heat resistance, acid resistance and alkali resistance. Anti-mold and moth-proof, good dimensional stability, easy to process, and easy to recycle.

The spunbond production technology can adapt to different types of polymers, the process is short, flexible and diverse, the technology is mature, the technology content is high, the degree of automation is high, and the spinning speed is multiplied, the single fiber strength is greatly improved, and the fiber is coming The thinner, the faster and faster the web formation, and the uniformity of the web formation is getting better and better. Its output has accounted for 60% -70% of the world's total non-woven fabric output, and its application range is becoming wider and wider.

It is precisely because of the simple production process, short process flow, low product cost, unique structure, and superior technical performance of spunbond nonwoven fabrics, it is widely used in the automotive industry, and its usage is much larger than other non-woven materials by area Weaving cloth. Spunbond non-woven fabrics can be used not only as various interior decoration materials for automobiles, but also as sealing and waterproof materials for automobiles, as reinforcing framework materials for automobiles, as well as various packaging protection materials for automobiles, and are also ideal for automobiles Industrial filter material.

In the production process of polypropylene spunbond nonwovens, filament breakage often seriously affects the normal production. The main performances are: leaking drops, drawing broken wires.

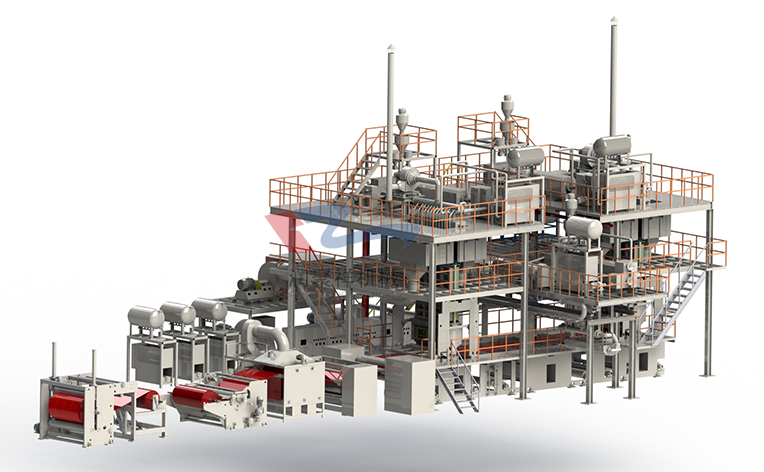

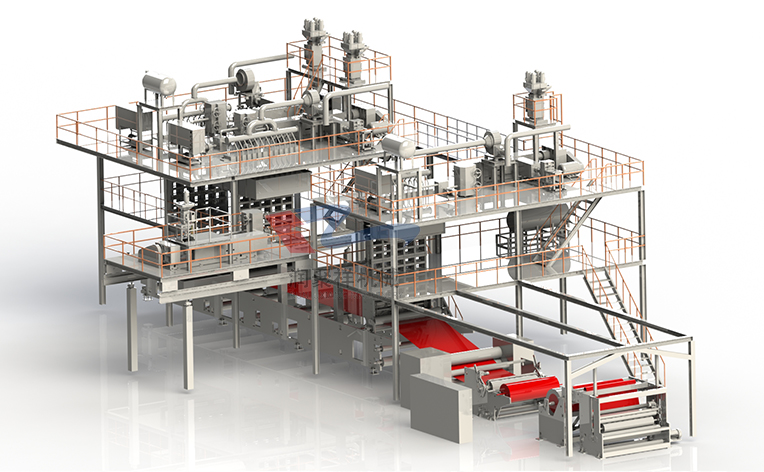

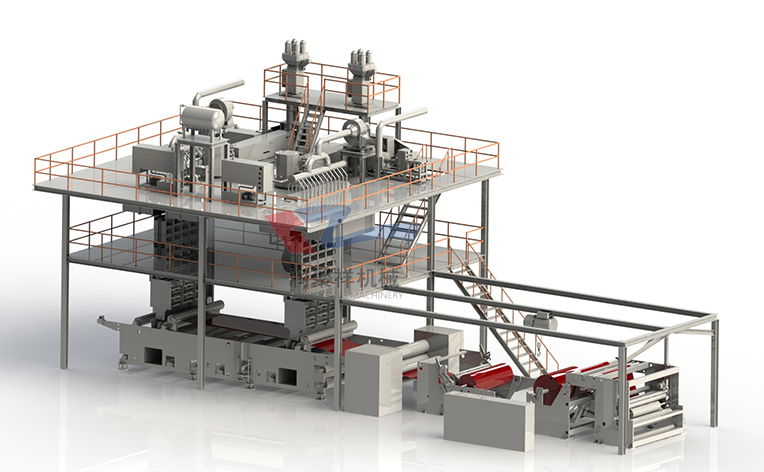

Qingdao Runjuxiang Machinery Co., Ltd. was established in Wenzhou in 1998. With the company's development and business expansion, it moved to Qingdao in 2008 and established Qingdao Runjuxiang Machinery Co., Ltd. Up to now, there are only more than 200 sets of mechanical processing and manufacturing equipment, and are equipped with professional testing equipment. So far, more than 200 production lines of polypropylene spunbond nonwoven fabric have been produced.

Qingdao Runjuxiang Machinery Co., Ltd. has established a perfect after-sales service system, eliminating the customer's worries, quick response, one-stop service, with the goal of "meeting the needs of customers", forge ahead and bravely climb.

If you want to know more about our company, please contact: Mr. Gu 18661750769 Website: http://www.qdrunjuxiang.com

- After the Minor Snow season, Qin

- Innovation and upgrading in the

- The non-woven fabric machinery o

- The operation of China's industr

- As the chill of November intensi

- The textile industry forges new

- What are the wide application fi

- A brief overview of the operatio

- Runjuxiang is deeply engaged in

- The economic operation of China'

- About RunJuXiang

- Company Profile

- Company Culture

- Non-woven production line

- Spunbond nonwoven production line

- Two-component Bi-Co

- Spun melted nonwoven production line

- Equipment Accessories

- Meltblown nonwoven production line

- Non-woven products

- News Center

- Company News

- Show Information

- Contact Us

- Contact RunJuXiang

- Online Message