- Contact:Ms. Zhang

- Cel:0086-18053229518

- Mail:info@qdrunjuxiang.com

- Add:Chengma Road, Qijialing Village, Tongji New District, Jimo City, Qingdao

Due to the current rapid development of the non-woven fabric industry, it is considered by most economists and entrepreneurs to be a sunrise industry in the new century. According to the survey data of CNITA (China Industrial Textiles Industry Association), the total output of non-woven fabrics in China is showing an upward trend year by year (increasing at an average annual rate of 15.00%), and the total output has ranked first in Asia. Synthetic fibers occupy a significant advantage in the production and development of nonwovens.

The use of new environmentally friendly materials and the penetration of high-tech technologies are fully reflected in the development of the non-woven fabric industry, and their roles have also been fully utilized. At the same time, non-woven fabrics have been widely used in all sectors of society, as well as in various economic sectors and industries, especially in the construction, auto repair, clothing and medical, aerospace and environmental industries. It is the most widely used in other fields. In addition, the application of non-woven fabrics in health care, especially sanitary products, has been expanding, creating a new development space for medical textiles, clothing textiles and textiles for vehicles, forming a high added value of non-woven fabrics. And a competitive advantage with high economic efficiency.

Non-woven production process is gradually mature

As far as the current development of non-woven fabrics is concerned, the production line is growing rapidly, and the production process is constantly maturing and perfecting in the process of production and development. At present, China's non-woven fabric production process has formed a meltblown non-woven production line, a spunbond non-woven production line, a needle-punched non-woven production line, a spunlace non-woven production line, a spray-bonded cotton production line and a high-grade imitation silk cotton production line. Advanced production technology. At the same time, large-scale and high-efficiency production lines invisibly indicate the continuous improvement and improvement of China's non-woven production capacity. According to relevant sources, at present, China has signed formal contracts with many foreign advanced production enterprises (German Frysler Machinery Manufacturing Co., Germany Dyro Machinery Manufacturing Co., Italy Yaseli Co., Ltd., etc.), and introduced them appropriately. On the basis of advanced materials such as filter materials, composite materials and artificial leather base fabrics, the production varieties of non-woven fabrics in China have been successfully enriched, and the quality and grade of non-woven fabric production in China have been improved. The quality of production equipment directly determines the production capacity and production efficiency to a large extent. As far as China's current non-woven fabric productivity is concerned, the production equipment is mainly made in China, and the price is about 1/3 of that of foreign advanced equipment. In the following, although the production efficiency may be slightly inferior, relying on domestic equipment can effectively reduce the production input and production cost of the non-woven fabric, which is conducive to further improving the market competitiveness of the enterprise and optimizing the economic benefits of the entire production process.

Distribution characteristics of non-woven fabrics in China

Compared with other provinces and cities, Guangdong is the main production, sales and application base of non-woven fabrics in China. In this region, disposable health care products, non-woven fabrics, industrial non-woven fabrics and spunbonded non-woven fabrics, etc., both in terms of production scale, production quality and output, or import and export trade volume are stable. Ranked first in China. In this area, it has certain advantages in the development of non-woven products and the introduction of advanced equipment, such as disposable medical articles, beauty products, and non-woven products such as handbags, sanitary trousers and suits. The scale of production is relatively large, and the quality of the products produced is relatively high, and the grades are also high. It has been exported to all parts of the world (about 70% or 80% of exports). Although the region has achieved certain achievements in the non-woven fabric industry, it is still in the process of continuous development and improvement. At the same time, many regions, including Jiangsu and Zhejiang, are also vying for new production lines, and are committed to continuous research and development. Non-woven high-tech and high-tech products.

The development of non-woven fabric production in China

With the continuous development of China's social economy and the increasing national strength, the living standards of the broad masses of the people have been significantly improved and improved. However, China's engineering construction has become an inexhaustible motive force for national development, which is one of the main reasons for this good situation. China's Three Gorges Project, environmental protection projects, real estate development and infrastructure construction are endless, and modern construction methods such as lightweight structures and continuous flat houses with larger and larger areas are more and more comprehensive in related fields. Promotion has further increased the quality requirements for roofing waterproofing. In addition, the rapid development of China's transportation industry in recent years is also a major factor in promoting China's economic development and the continuous improvement of people's living standards. According to relevant statistics, the number of cars produced in China is up to one million each year. The masses of people are convenient to purchase large quantities of cars for travel. In the production and manufacturing process of each car, the material of the trunk, the material of the roof, and the insulation Materials and shock-proof materials are inseparable from non-woven fabrics, and must be used in more than ten kilograms. Moreover, the progress and development of various industries in various fields in China will strongly stimulate the consumption of various types of sanitary absorbent products, air filtration materials, medical and hygiene products, and waterproof materials and packaging materials, and these fields will also be fierce in the development process. Competition, and also led to many problems such as competing price reduction and production sluggishness and low efficiency, which provides a broad market and good development prospects for the high quality and versatile non-woven fabric.

The development direction of China's non-woven fabric production

From a practical point of view, non-woven handbags made mainly of polyester and polypropylene have been widely used in various fields. This type of non-woven handbag is not only difficult to be wet by water, it is suitable for disposable packaging of clothing, cotton fabrics and knitwear, and it is cheaper and recyclable. It can extend the use of handbags on the basis of effectively replacing paper handbags. Life expectancy can also effectively reduce the pollution of ecological environment by items such as plastic bags. In addition, non-woven handbags have gradually been accepted by domestic and foreign markets, known as globally recognized green products. It is not difficult to see that the future market of non-woven handbags is very broad, and the cost and technical content required for the procurement of raw materials, production and processing are not high, thus pointing out a new new for China's non-woven industry. Good development direction. At the same time, from the perspective of many aspects of future development, China will have further breakthroughs and developments in the field of non-woven needle-punching filter materials. In the near future, China will also develop higher-quality, high-performance filters. New varieties.

In short, non-woven fabrics have gradually become an emerging industry in the global market, and China has made considerable achievements in the production and development of non-woven related industries, but the global economy is constantly developing, and human needs are also increasing. Looking forward to the future development trend of the non-woven industry in China, it is necessary to broaden the corresponding market.

There are many kinds of non-woven machinery, which not only enriches the market, but also allows manufacturers to have more choices, but it also causes certain problems for buyers. How to choose the product that suits you at a better price in a mixed environment, it is a great challenge for every buyer, and it needs to be identified with the fire eye. However, focusing on the manufacturing service, we will prepare buyers for the purchase of non-woven mechanical products to solve your purchasing problems and let you bypass the procurement trap. In addition, it is also based on the actual needs of the buyer.

Non-woven machinery mainly includes: non-woven bag machine, non-woven slitting machine, non-woven surgical sewing machine, non-woven filter cotton weaving machine, non-woven shoe cover machine, non-woven glove machine, non-woven Cloth machine, non-woven doctor hat machine, non-woven nurse cap machine, non-woven pillow core machine, non-woven eye mask machine non-woven punching machine, non-woven rewinding machine and other machines. Non-woven machinery is a general term for the production of non-woven products, and the overall modular design, compact and reasonable structure.

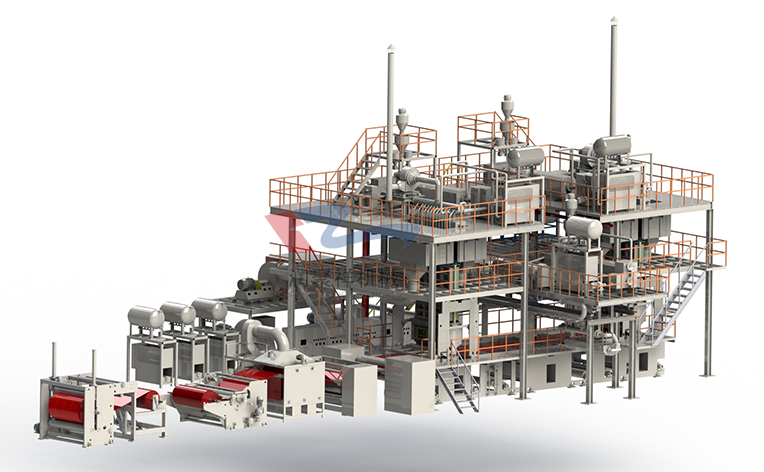

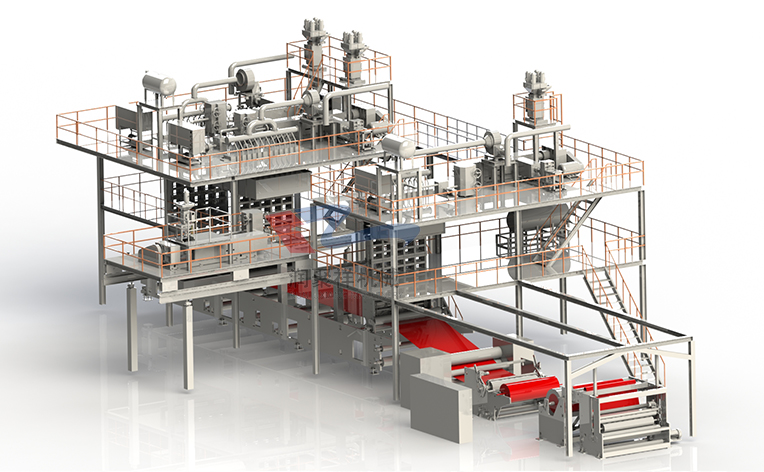

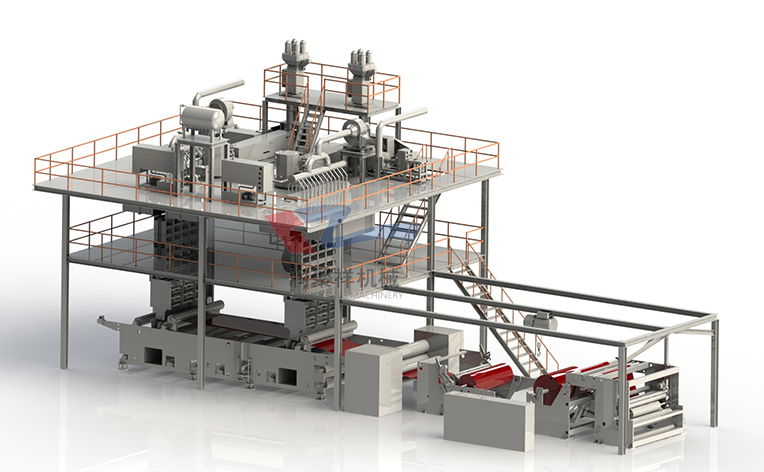

The company's equipment uses advanced touch screen operation and stable performance. The fiber fineness of the produced product is about 1.5-2 denier, and the vertical and horizontal tensile force of the product reaches or exceeds the national standard. The production line has passed the practice of several production equipments, digested and absorbed the advanced technology of similar equipment from abroad, and adopted the most advanced “slit negative pressure pulling net” technology in the non-woven fabric industry. The design is reasonable, the specifications are complete and the performance is superior. The uniform color is uniform and the thickness is uniform. Especially when making powder, the cloth surface is even and the hand feel is moderate. It is suitable for polypropylene raw materials, producing white, colored, anti-aging, antistatic, antibacterial, Various spunbonded nonwoven fabrics such as flame retardant.

If you would like to know more about our company, please contact: Mr. Gu 0315-5117262 Website: http://www.qdrunjuxiang.com

- The non-woven fabric machinery o

- The operation of China's industr

- As the chill of November intensi

- The textile industry forges new

- What are the wide application fi

- A brief overview of the operatio

- Runjuxiang is deeply engaged in

- The economic operation of China'

- In September, the production sea

- On the eve of the "Golden Septem

- About RunJuXiang

- Company Profile

- Company Culture

- Non-woven production line

- Spunbond nonwoven production line

- Two-component Bi-Co

- Spun melted nonwoven production line

- Equipment Accessories

- Meltblown nonwoven production line

- Non-woven products

- News Center

- Company News

- Show Information

- Contact Us

- Contact RunJuXiang

- Online Message