- Contact:Ms. Zhang

- Cel:0086-18053229518

- Mail:info@qdrunjuxiang.com

- Add:Chengma Road, Qijialing Village, Tongji New District, Jimo City, Qingdao

A few days ago, in the printing and dyeing workshop of Zhejiang Jinsuo Printing and Dyeing Co., Ltd., along with the roar of the machine, several automated production lines continued to operate, and the colorful fabrics were freshly baked. "In the past, these data required manual statistics, and now all of them are handed over to the machine." Tong Yunxia, the vice chairman of the company, pointed to the number of beating on the computer screen and told reporters that this set of production execution system called MES can Accurately update the raw material consumption, energy consumption, production quantity and other data in the production process in real time. “Not only the labor cost is reduced, but also help us analyze the order status and arrange the output.”

As a pilot project for the transformation of traditional industries in the province, after years of development, Lanxi textile industry still faces challenges such as low profit margin, low innovation, insufficient talent support, rising factor costs, and blocked industrial chain extension. In recent years, Lanxi has adhered to the direction of digital transformation, and fully promoted the intelligent transformation of “machine substitution” in the textile industry, and realized the optimization and upgrading of production equipment, process technology, enterprise management and sales channels.

Last year, the expert group of the Provincial Intelligent Manufacturing Expert Committee entered Lanxi to help local enterprises to carry out the "enterprise digital manufacturing, industry platform service" work. Under the guidance of experts, Jinsuo Printing and Dyeing, Xinlan Textile, Qijin Textile, Weichen Textile, Xinhai Textile and other enterprises continue to deepen the digital transformation of enterprises.

A series of initiatives have achieved remarkable results. “Lanxi currently has more than 30,000 internationally leading looms, which can produce white cloth of 2.2 meters per kilowatt hour, which is much higher than the average level of 0.7 meters in the same industry in the country; less than 30 workers per 10,000 spindles, far lower than The average level of 80 people in the same industry in China," said Sun Weidong, deputy director of Lanxi City Economic and Information Technology Bureau.

The road to intelligent development is getting stronger and stronger. On June 26, at the Lanxi·China Cotton Industry Innovation and Development Conference hosted by China Cotton Textile Industry Association and Lanxi Municipal Government, Lanxi officially launched the establishment of the textile industry demonstration manufacturing city. It is planned to gradually realize Lanxi through three years or so. The textile enterprise's equipment network, data visualization, document paperless, process transparency, workshops and people, service platform, built a number of intelligent production lines, intelligent workshops, intelligent engineering. "This is an inevitable choice for taking the road of innovation and development, green and intelligent development, and is also a concrete measure to promote the high-quality development of the industry." The main person in charge of the Lanxi Municipal Committee said.

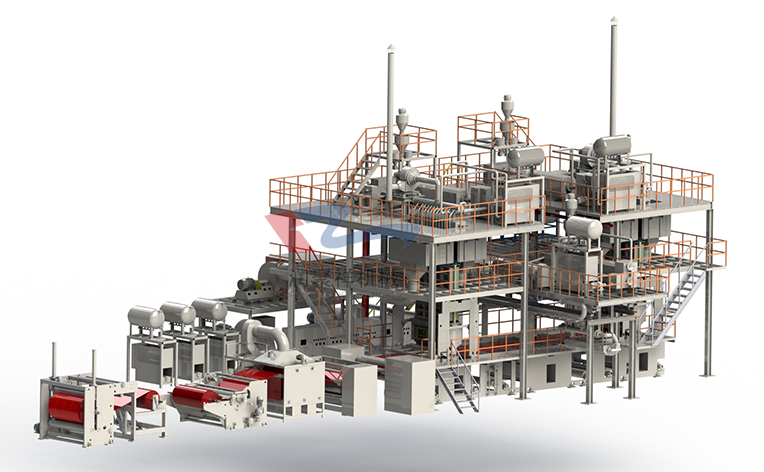

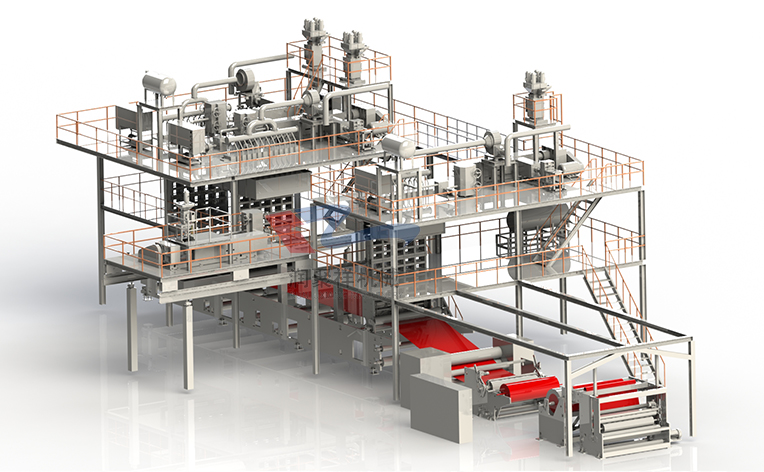

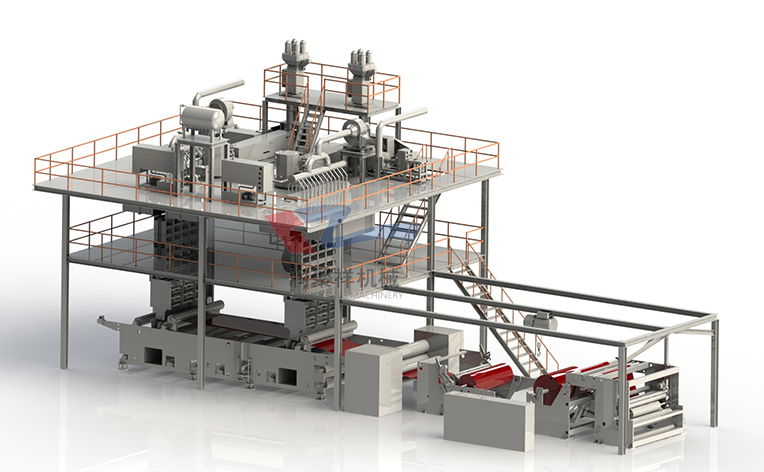

Qingdao Runjuxiang Machinery Co., Ltd. was established in Wenzhou in 1998. With the development of the company and the expansion of its business, it moved to Qingdao in 2008 and established Qingdao Runjuxiang Machinery Co., Ltd. Up to now, only more than 200 sets of machining and manufacturing equipment, and equipped with professional testing equipment, have produced more than 200 production lines of polypropylene spunbonded non-woven fabrics.

If you would like to know more about our company, please contact: Mr. Gu 0315-5117262 Website: http://www.qdrunjuxiang.com

- After the Minor Snow season, Qin

- Innovation and upgrading in the

- The non-woven fabric machinery o

- The operation of China's industr

- As the chill of November intensi

- The textile industry forges new

- What are the wide application fi

- A brief overview of the operatio

- Runjuxiang is deeply engaged in

- The economic operation of China'

- About RunJuXiang

- Company Profile

- Company Culture

- Non-woven production line

- Spunbond nonwoven production line

- Two-component Bi-Co

- Spun melted nonwoven production line

- Equipment Accessories

- Meltblown nonwoven production line

- Non-woven products

- News Center

- Company News

- Show Information

- Contact Us

- Contact RunJuXiang

- Online Message