- Contact:Ms. Zhang

- Cel:0086-18053229518

- Mail:info@qdrunjuxiang.com

- Add:Chengma Road, Qijialing Village, Tongji New District, Jimo City, Qingdao

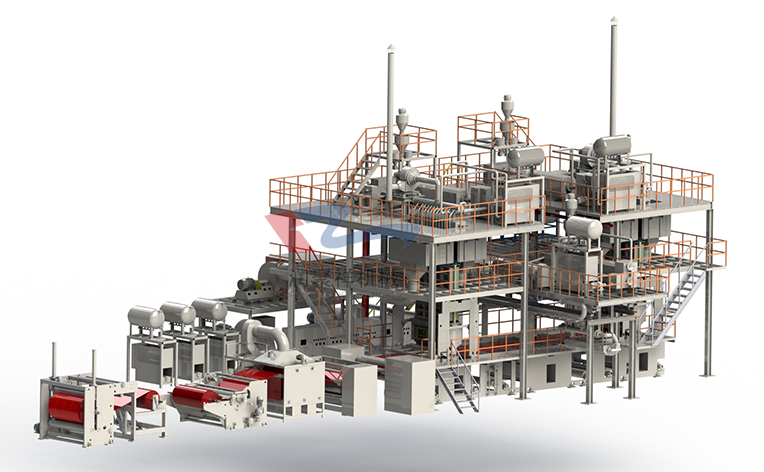

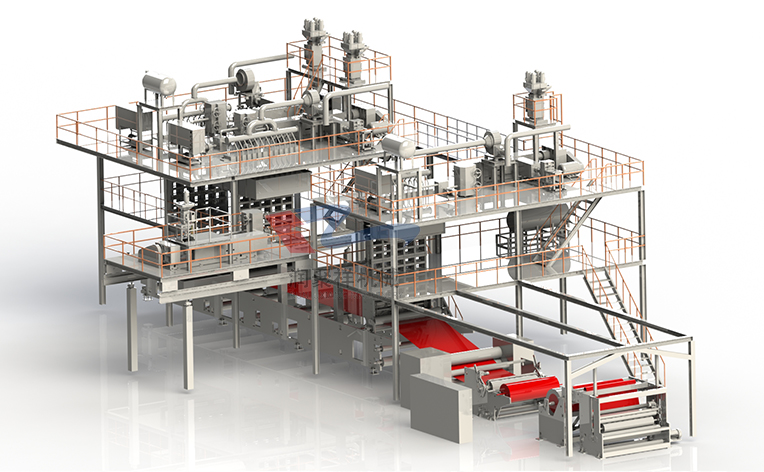

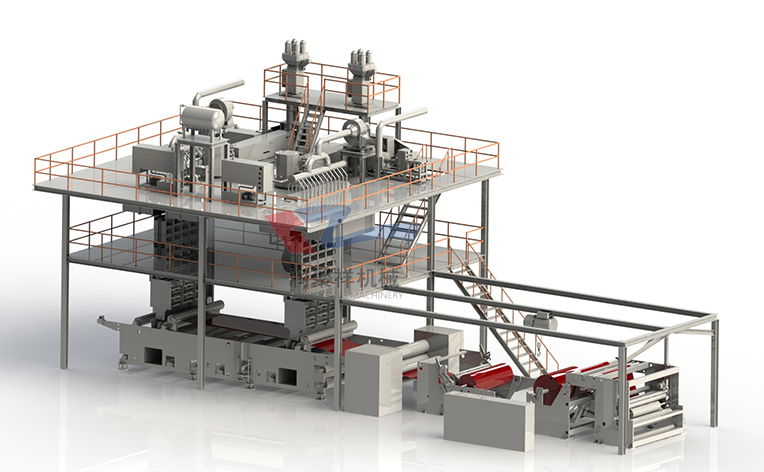

Introduction of non-woven production line

The rolling mill is driven by direct power, hard gear reducer and high stability universal coupling. The bearing adopts oil-cooled overtemperature and oil shortage warning system. The roll surface adopts peripheral drilling technology to ensure the overall temperature divergence. The box design is advanced, the fluid distribution is uniform, to ensure that the waste is intermittent, not merged, no holes, improve the product pass rate. In addition, the operation of the spunbonded non-woven production line is relatively simple and easy for users to get started.

After many years of summary by designers, the air duct adopts the ordinary slit overall drafting design to ensure the average fiber laying, the fiber fineness reaches about 3 deniers, and the vertical and horizontal strength of the product meets or exceeds the specification.

Non-woven fabrics are made of polyester fibers and polyester fibers, which are made through the knitting process and can be made with different thicknesses, feel and hardness. With the development of science and technology, the production of non-woven fabrics has been replaced from manual to mechanical production, and its emergence has solved thorny problems such as slow processing efficiency.

Qingdao Runjuxiang Machinery Co., Ltd. is a professional manufacturer of non-woven equipment, non-woven machinery and spunbond non-woven equipment. Manufacturing width: 1.6 meters, 2.4 meters, 3.2 meters, 4.2 meters, 8 grams weight - 250 grams/square meter, and can design and produce other specifications according to customer needs.

- In the prelude of early winter,

- The volume of industrial textile

- After the Minor Snow season, Qin

- Innovation and upgrading in the

- The non-woven fabric machinery o

- The operation of China's industr

- As the chill of November intensi

- The textile industry forges new

- What are the wide application fi

- A brief overview of the operatio

- About RunJuXiang

- Company Profile

- Company Culture

- Non-woven production line

- Spunbond nonwoven production line

- Two-component Bi-Co

- Spun melted nonwoven production line

- Equipment Accessories

- Meltblown nonwoven production line

- Non-woven products

- News Center

- Company News

- Show Information

- Contact Us

- Contact RunJuXiang

- Online Message