- Contact:Ms. Zhang

- Cel:0086-18053229518

- Mail:info@qdrunjuxiang.com

- Add:Chengma Road, Qijialing Village, Tongji New District, Jimo City, Qingdao

Precautions for daily operation of nonwoven production line machinery

I believe that everyone will see a lot of mechanical equipment in our lives. That is because our technology is developing rapidly, so many of our equipment are being updated. However, it is because of the emergence of some mechanical equipment that many production operations are There is no need to do it manually, just like the emergence of non-woven fabric production machinery, which gradually replaced traditional manual production, and the quality of products produced by non-woven fabric production machinery has far surpassed that of hand-made production, so this is a lot of people. However, there are still many precautions that need to be understood in the daily operation of nonwoven production line machinery, let us take a look.

Precautions for daily operation of nonwoven production line machinery

Mechanical components and maintenance of nonwoven production lines, do not allow excessive moisture and oil to enter the pressure system, in order to avoid failures, shorten the life of the cylinder barrel, ensure dry and clean air, if possible, freeze dryer, check the conversion When the oil volume of each inner cup of the device is sufficient, the pressure relief valve is not used for a long time at the rear end and should be pushed. When it stops working, the power switch and compressed air control valve should be turned off; the shaft barrel and each part should avoid magnetic loss ; Assembly workbench side sliding seat parts and precision and highly complex parts should be wiped clean frequently and oiled for maintenance to prevent the influence of rust accuracy. Pay attention to the environment and machine maintenance, cyclophosphamide induces the cloth making workshop environment to keep clean, especially the plate-making glass, which needs to be cleaned up before work, from an ordinary cleaning and maintenance development, voltage, power detection, it should be ensured that the voltage is used in its use In order to avoid the voltage is too high or too low, it should be set in a cold storage dark room or a low temperature, dry place, especially to avoid sinking, do not use contaminated or do not touch with hands. The uniform thickness of the rubber wiper, the daily production often does not pay attention to this work, and causes local damage to the cloth production board.

If you want to know more about our company, please contact: Mr. Gu 0315-5117262 Website: http://www.qdrunjuxiang.com

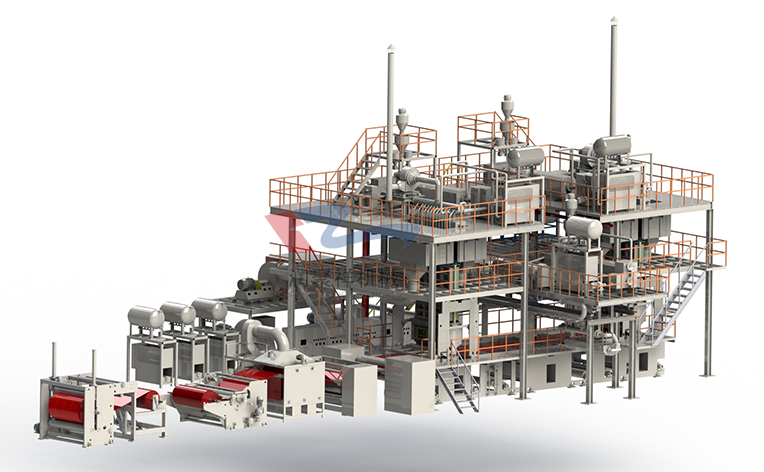

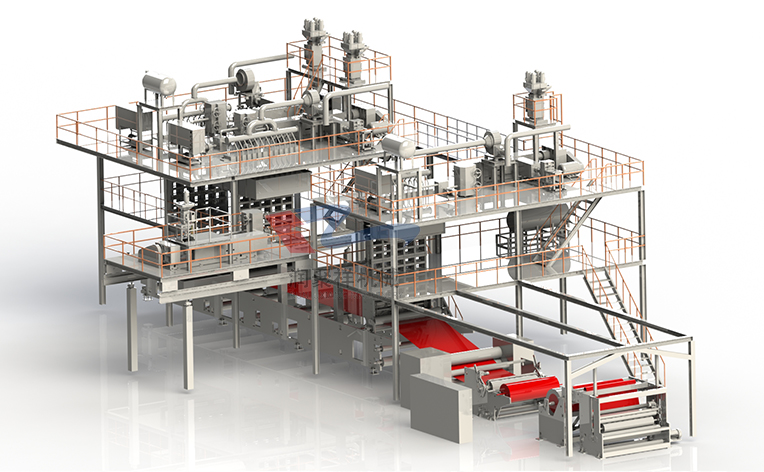

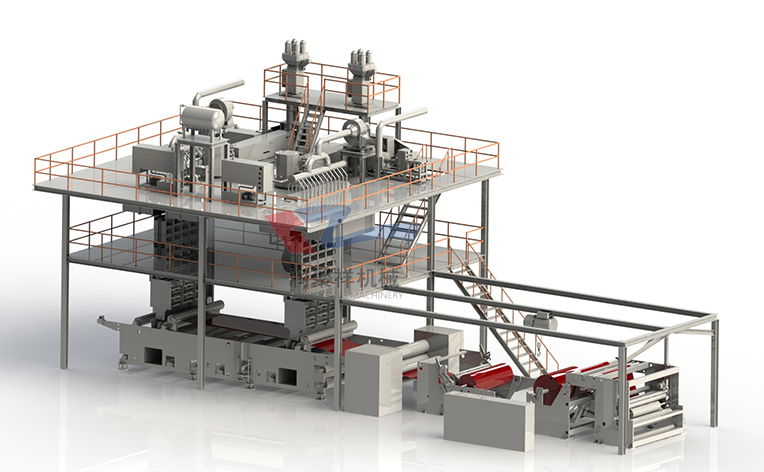

Qingdao Runjuxiang Machinery Co., Ltd. was established in Wenzhou in 1998. With the company's development and business expansion, it moved to Qingdao in 2008 and established Qingdao Runjuxiang Machinery Co., Ltd. Up to now, there are more than 200 sets of mechanical processing and manufacturing equipment, equipped with professional testing equipment, and more than 200 production lines of polypropylene spunbond non-woven fabrics have been produced so far.

Qingdao Runjuxiang Machinery Co., Ltd. has established a complete after-sales service system, which relieves customers from worries, responds quickly, provides one-stop service, and aims at "meeting customer needs", forging ahead and climbing bravely.

If you want to know more about our company, please contact: Mr. Gu 18661750769 Website: http://www.qdrunjuxiang.com

- In the prelude of early winter,

- The volume of industrial textile

- After the Minor Snow season, Qin

- Innovation and upgrading in the

- The non-woven fabric machinery o

- The operation of China's industr

- As the chill of November intensi

- The textile industry forges new

- What are the wide application fi

- A brief overview of the operatio

- About RunJuXiang

- Company Profile

- Company Culture

- Non-woven production line

- Spunbond nonwoven production line

- Two-component Bi-Co

- Spun melted nonwoven production line

- Equipment Accessories

- Meltblown nonwoven production line

- Non-woven products

- News Center

- Company News

- Show Information

- Contact Us

- Contact RunJuXiang

- Online Message