- Contact:Ms. Zhang

- Cel:0086-18053229518

- Mail:info@qdrunjuxiang.com

- Add:Chengma Road, Qijialing Village, Tongji New District, Jimo City, Qingdao

The large-scale development of domestic melt-blown nonwovens began at the beginning of this century and reached its peak in 2009. In the last decade or so, due to the impact of the European and American debt crisis and the slowdown of domestic economic growth, the development rate has slowed down. Be rational.

Compared with multinational companies, although some domestic melt-blown nonwovens manufacturers have already had a certain scale, and they have achieved some gratifying research results in terms of independent research and development and product quality, overall, the business model is still Small and scattered situation, low concentration of industry, low level of specialization; enterprises scattered in various industries and groups, backward technology, inefficient equipment, small scale of production, can not form a sound system and strong overall competitiveness.

Related Report: Beijing Puhua Policy Information Consulting Co., Ltd. "2019-2025 Melt-blown Nonwovens Industry Operation Situation Analysis and Prospect Forecast Advisory Report"

In terms of R&D investment and production and demand linkage, the world's technology and equipment levels are rapidly improving and developing. Manufacturers from various countries are also committed to eliminating and updating their backward technologies and equipment that are not in line with today's development. Domestic melt-blown nonwovens. In recent years, there have been some progress in the technology and equipment through the introduction and digestion of foreign technology and equipment, but the overall strength is weak, the industrial chain is not coordinated enough, and the special fiber raw materials, equipment products and application fields cannot form an effective docking. The application development potential of the weaving industry is not fully reflected, and there are more backward production capacity.

The third weakness of domestic meltblown nonwovens is that the products are still in the low-end market and the added value of the products is low. The early stage of the development of China's meltblown nonwovens was mainly developed by using cheap labor in an extensive manner. The technology and equipment are relatively backward, and the product market is mainly positioned in the low-end and mid-range. For example, automotive interior fabrics produced by domestic meltblown fabrics can only be used for mid- and low-end cars, high-end car interior materials are provided by multinational companies, and high-end biomedical textiles are mainly imported. Some multinational companies occupy the high-end and active position of the global vertical division of labor by virtue of technology and supply chain integration advantages, and monopolize most high-tech and high value-added melt-blown fabric markets.

2. The main obstacles to entering the industry

(1) Technical barriers

The competition among melt-blown nonwovens is first of all the competition between process technology and R&D strength. Melt-blown method is an unsteady process, and the production process control is more complicated. Although the principle of melt-blown spinning is clear, the main structure of the equipment is clear, but many key technologies and production process control are basically not used by equipment manufacturers. Mastered, these key technologies affect the quality of the product and the internal structure of the material, and are directly related to the application and promotion environment of the product. Therefore, the core manufacturing technology of meltblown nonwovens is not bought, but the manufacturers of meltblown nonwovens are constantly exploring according to market demand and product positioning, that is, “the key technology that cannot be bought with money”.

The melt-blown process is also a field with high technical content, involving many disciplines such as polymer science, fluid mechanics, gas flow, spinning, thermodynamics and electrochemistry. It is a combination of traditional spinning, subsequent finishing, and composite processing. The series of combined processes have different requirements for fiber structure and application form. A single device cannot produce all the different products, and a single process parameter cannot produce all the different products. Therefore, the competition between process technology and R&D strength is an important feature of the industry.

(2) Funding barriers

Melt-blown nonwovens are widely used in different fields, but different products and different application fields require different specialized production equipment. There are no general-purpose equipments that can produce many different products. Therefore, in general, melt-blown nonwovens are produced. The equipment investment required is large. For some market segments with high market capacity, such as baby diapers, women's hygiene materials, automotive filter materials and other market segments, taking into account the downstream customers' capital occupation of manufacturers, etc., it is also objectively increased. The financial barriers of the entrants.

(3) Professional talent barriers

The industry has high requirements for multidisciplinary integrated technology development and cross-disciplinary cooperation of technical teams. The qualified technical teams generally include materials science talents, compound engineering talents, and mechanical structure talents. Taking the coating compound technology as an example, each technical service engineer usually needs years of technical accumulation to master the technical difficulties in equipment operation and provide high-quality technical service support to customers. The scientific and effective combination of cross-professional and multi-disciplinary technical teams and the correct market direction guidance can meet the requirements of technology R&D, product design and service support in the industry, and objectively form a high barrier for professional talents.

Nonwoven application

Made of microfibers for good isolation and filtration properties.

Sanitary materials baby and child hygiene products, ladies hygiene products, liners, hydrophilic septa, etc.

Hot melt adhesive material

The absorbent material absorbs and filters materials such as wiping cloth, oil adsorbing material, and liquid absorbing material (benzene, water, blood), gasoline, air, liquid (benzene, water, blood).

The meltblown nonwoven process is a type of polymer extrusion process that originated in the early 1950s. In the early 1950s, the US Naval Laboratory began to develop filtration materials with ultra-fine filtration effects in order to collect radioactive particles generated by nuclear tests. The research results were published in 1954.

In the mid-1960s, Exxon of the United States further studied the process and cooperated with Accurate to manufacture the first meltblown equipment prototype and applied for a patent. At present, in addition to Exxon's proprietary technology of melt-blown technology, other companies (such as 3M in the US, Hills in the US, Freudenberg in Germany, etc.) have also successfully developed their own melt-blown nonwoven technology.

Since the 1980s, meltblown nonwovens have grown rapidly around the world, maintaining an annual growth rate of 10%-12%. Melt-blown nonwoven materials have excellent performance in filtration, bacteria inhibition, adsorption, warmth, waterproof, medical and health, etc., and have attracted extensive attention from domestic and foreign companies. In recent years, new materials, new processes and new products of melt-blown nonwovens have emerged, and the application fields are expanding.

The following is the production process and principle of the melt-blown nonwoven technology introduced by Run Juxiang Xiaobian. The melting process has been analyzed in recent years from the aspects of meltblown nonwoven production technology, meltblown new materials and meltblown nonwoven products. The development of spray non-woven technology.

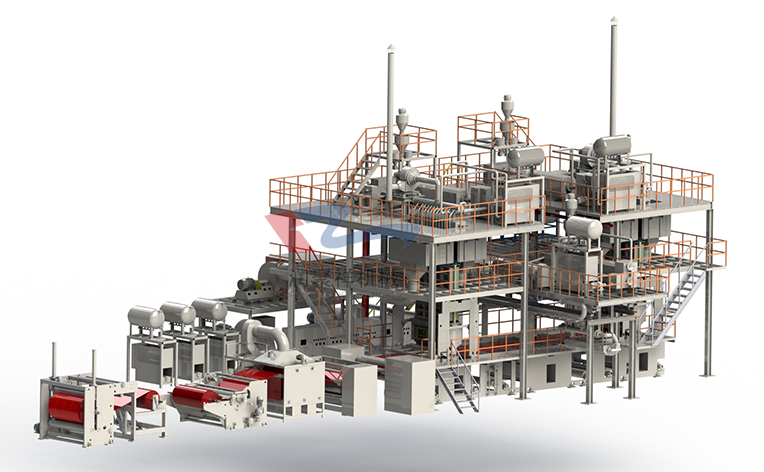

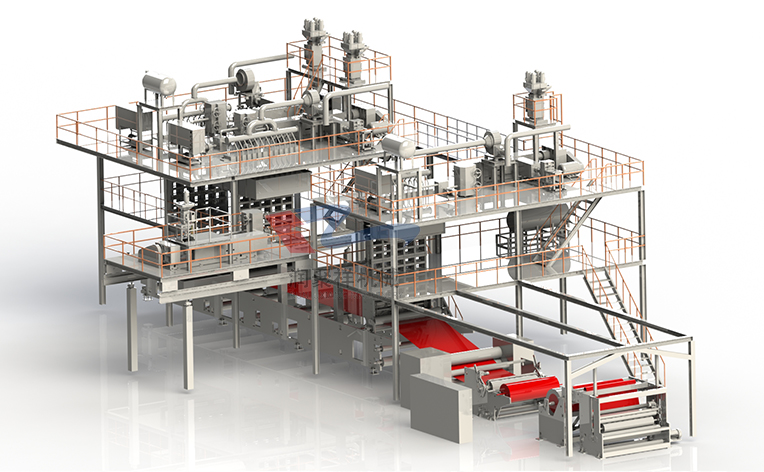

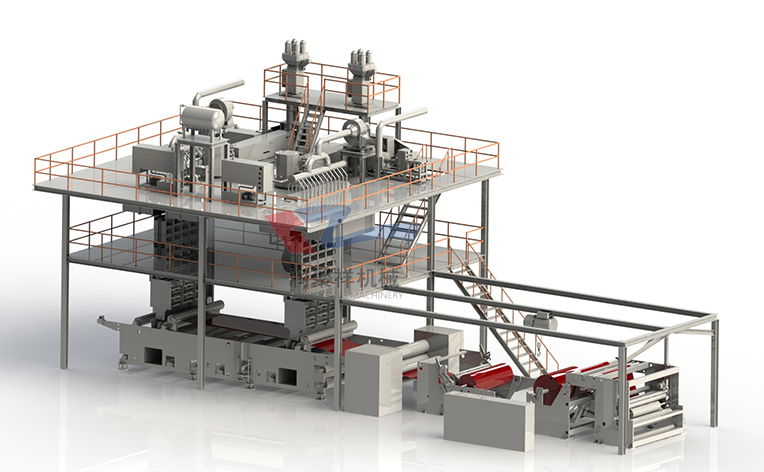

M meltblown nonwoven production line (single die head) of Qingdao Runjuxiang Machinery Co., Ltd.

The maximum production speed can reach 100 m / min.

4.2 meter production line, technical parameters

The weight range is 8-80 g/m2. The maximum speed is 100 m/min. The production capacity is 2300 tons/year.

3.2 meter production line, technical parameters

The weight range is 8-80 g/m2. The maximum speed is 100 m/min. The production capacity is 1700 tons/year.

2.4 meter production line, technical parameters

The weight range is 8-80 g/m2. The maximum speed is 100 m/min. The production capacity is 1300 tons/year.

1.6 meter production line, technical parameters

The weight range is 8-80 g/m2. The maximum speed is 100 m/min. The production capacity is 850 tons/year.

Qingdao Runjuxiang Machinery Co., Ltd. is a professional manufacturer of meltblown nonwovens and meltblown nonwovens. Qingdao Runjuxiang Machinery Co., Ltd. was established in Wenzhou in 1998. With the development of the company and the expansion of its business, it moved to Qingdao in 2008 and established Qingdao Runjuxiang Machinery Co., Ltd. Up to now, only more than 200 sets of machining and manufacturing equipment, and equipped with professional testing equipment, have produced more than 200 production lines of polypropylene spunbonded non-woven fabrics.

Qingdao Runjuxiang Machinery Co., Ltd. has established a perfect after-sales service system, which eliminates customers' worries, quick response, one-stop service, and aims to “satisfy customer needs”.

If you would like to know more about our company, please contact: Mr. Gu 0315-5117262 Website: http://www.qdrunjuxiang.com

- In the prelude of early winter,

- The volume of industrial textile

- After the Minor Snow season, Qin

- Innovation and upgrading in the

- The non-woven fabric machinery o

- The operation of China's industr

- As the chill of November intensi

- The textile industry forges new

- What are the wide application fi

- A brief overview of the operatio

- About RunJuXiang

- Company Profile

- Company Culture

- Non-woven production line

- Spunbond nonwoven production line

- Two-component Bi-Co

- Spun melted nonwoven production line

- Equipment Accessories

- Meltblown nonwoven production line

- Non-woven products

- News Center

- Company News

- Show Information

- Contact Us

- Contact RunJuXiang

- Online Message