- Contact:Ms. Zhang

- Cel:0086-18053229518

- Mail:info@qdrunjuxiang.com

- Add:Chengma Road, Qijialing Village, Tongji New District, Jimo City, Qingdao

What is the difference between Chinese dyeing factories and Italian dyeing factories? Foreign experts tell you how far from the top of the pyramid

Undoubtedly, Italian fabrics represent the top of the world fabric “pyramid”. They are the “speakers” of high-end, technology and crafts, and are highly sought after by top international brands. Nowadays, Chinese textile enterprises are also sparing no effort to “explore the territory and expand the territory”, and they are scrambling to expand their own “territory”, but few can open the door to the international high-end market.

Recently, Roberto Steffenino, technical consultant of Foshan Datang Textile Printing and Dyeing Fabric Co., Ltd., summarized his experience in textile printing and dyeing enterprises in Europe and China at the 8th National Printing and Dyeing Industry Management Innovation Conference. And gave advice on the problems encountered by Chinese printing and dyeing companies.

Question 1: Hardware boom is difficult to hide software missing

Robert believes that although many printing and dyeing equipments in many factories in China are advanced, and imported products account for a large proportion, it can be said that the "hardware" link is not inferior to European companies, but the "software" of Chinese technicians in terms of quality and automation management. At the link, there is still a big gap with textile companies in developed countries such as Italy. “Because of the high labor costs in Europe, Italian textile companies generally use automation equipment instead of manpower to carry out refined management and control of the production process,” he said.

For example, Robert TVU, the largest dyeing enterprise in Europe, attaches great importance to employee training. In order to ensure product quality, it also has its own product testing room to provide customers with reports. The degree of automation of the entire factory is quite high, and the progress of each process can be found in the program. The computer color matching system has 80,000 dyeing prescriptions in the memory, which is convenient for testing and dyeing in the dyeing workshop, thus reducing the management caused by labor. Increase in error and cost.

“It is not difficult to find that the company’s management framework is institutionalized, and this is the key to a company’s long-term success.” Robert believes that compared with Italian textile companies, Chinese textile companies are the main There are several aspects of management defects: low degree of specialization, lack of spirit of using theory to guide practice; too conservative, lack of exploration spirit of new tools, new things, new tools; less attention to the cleaning, maintenance and maintenance of equipment; Workers' working environment, workers' safety production and health are relatively lacking in attention and supervision; they are not aware of the regulations of the international textile dyeing and finishing industry; they are not concerned about the collection and control of standard operating parameters in the process of production; Awareness of standardization, standardization, and institutionalization of work. Managers are less aware of self-improvement and are not adequately focused on training employees.

In response to the above problems, Robert stressed that China's textile enterprises should first streamline the organization, set the posts and responsibilities, formulate a clear organizational structure, and optimize the human resources of the enterprise. Secondly, establish a supervision and restraint mechanism for each link, so that the process handover has inspection and quality. There are countermeasures for pre-control, and quality management has been reviewed. Finally, it is to improve the professional quality of managers and accelerate the process of promoting the development of enterprise information.

Question 2: Insufficient development leads to weakness

Through years of work summary, Robert found that Chinese companies pay more attention to the front processing and printing and dyeing links, but the emphasis on the application and development of finishing technology is not too high. “Printing and dyeing finishing is the most flexible part of the entire textile production chain. Italian companies have decades of technical accumulation of textile auxiliaries in this segment, and they are flexible through various types of finishing equipment. The use of physical and chemical methods for finishing and increasing the added value of products. There are still many places for Chinese companies to learn."

In addition, Robert believes that insufficient investment in design development and technology research and development is also widening the gap between China and European printing and dyeing companies. “Italy's high-end home textile fabric company Seteria Bianchi srl is a company with a total of 80 employees. R&D and technical personnel account for 1/3 of the total number of people. There are 25,000 designs and 1,000 updates every year. It is a famous brand such as Vans Zhe. High-grade fabrics are available, but the order quantity is small, but the unit value is up to 100 Euro/m2."

He pointed out: "Some Chinese printing and dyeing companies claim that the number of new products reaches three digits each year, but most of them only change in terms of craftsmanship, patterns, colors, etc. Even products with higher 'newness' content are often followed. Leading and trailing products. There are fewer original new products with high technical content and strong competitiveness."

Robert admits that the gap between product design and consumer markets has led to different development ideas for Chinese and Italian companies. He said that most of the products of Italian companies are oriented to the high-end market in the fashion field. The scale of their enterprises is generally small, and they can undertake orders with multiple series, small batches and tight time requirements. This is also not available to most Chinese printing and dyeing companies.

Question 3: The concept is not consistent, causing the stick to be blocked

Today, many family businesses suffer from the problem of “crossing the bar”. The printing and dyeing industry is no exception. Many Chinese printing and dyeing family enterprises are not willing to engage in the real economy like their fathers, but to transform into a virtual economy.

“In Europe, this is also very common.” Robert said that he believes that it is not a problem if the second generation of the family business wants to switch to another area. “A family needs to respond flexibly if it wants to continue its wealth. If a new generation thinks that society has changed, investing in the real economy is no longer the best choice, but developing into an intangible economy such as the financial or Internet industry. It is also a good one. select."

“The older generation needs communication with a new generation of people. Of course, how to conduct effective and open communication is a difficult problem, especially on sensitive issues. People always think that the older generation is more intelligent and experienced, so they often lead young people. People, in fact, we should listen more to young people’s ideas and trust them. Family businesses should have a transparent communication system where members can sit down and analyze current market trends.” Robert said that the key to future family business success It is not that the children in the family must become the leaders of the enterprise, but the identity control enterprise as a shareholder. “Families can hire professional managers who understand the industry to manage the business, and family members can be supervised,” he added.

Robert concluded: "At present, the situation of the printing and dyeing industry is high and the situation, the focus of the company, in addition to how to pass on, should focus on the industry. The so-called 'entrepreneurial difficulties, more difficult to keep business', want to break the three-generation 'curse', Today's entrepreneurs should pay attention not only to the development of their own industries, but also to the increasingly cumbersome corporate management and policy trends."

- After the Minor Snow season, Qin

- Innovation and upgrading in the

- The non-woven fabric machinery o

- The operation of China's industr

- As the chill of November intensi

- The textile industry forges new

- What are the wide application fi

- A brief overview of the operatio

- Runjuxiang is deeply engaged in

- The economic operation of China'

- About RunJuXiang

- Company Profile

- Company Culture

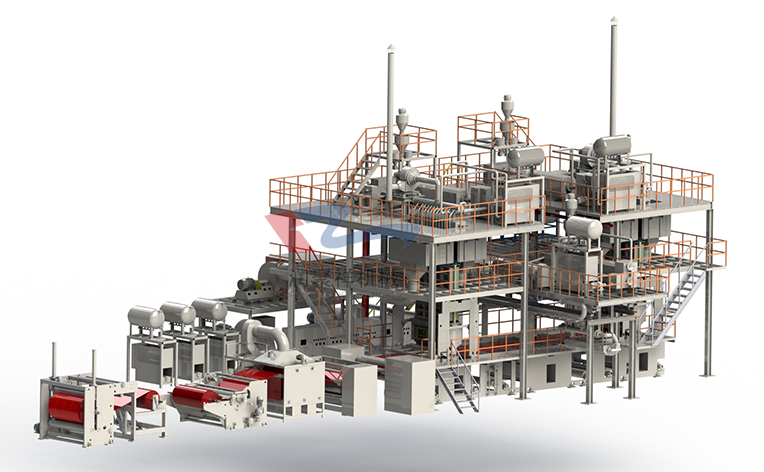

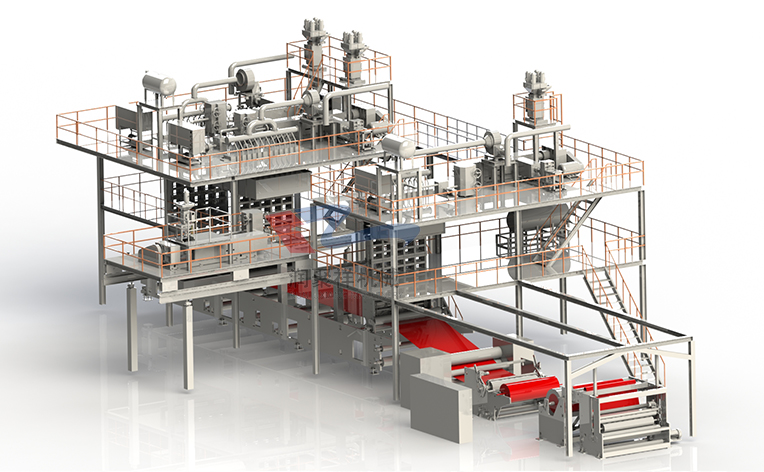

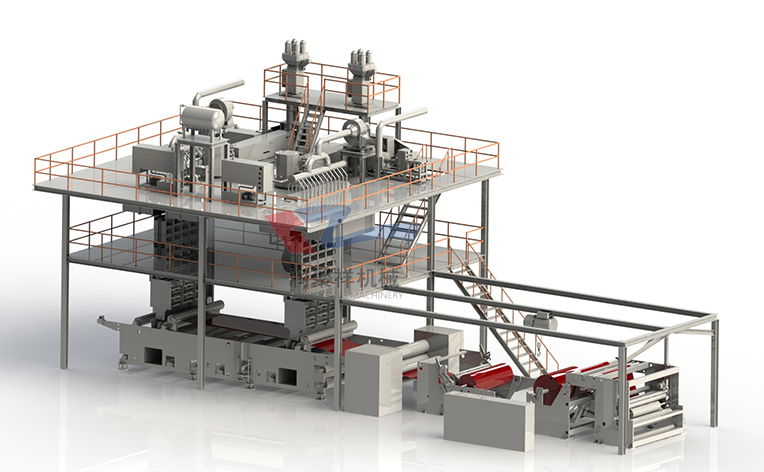

- Non-woven production line

- Spunbond nonwoven production line

- Two-component Bi-Co

- Spun melted nonwoven production line

- Equipment Accessories

- Meltblown nonwoven production line

- Non-woven products

- News Center

- Company News

- Show Information

- Contact Us

- Contact RunJuXiang

- Online Message