- Tel:0086-0086-0532-86655395

- Cel:0086-0086-18661750769 13705321539

- Mail:info@qdrunjuxiang.com

- Add:Chengma Road, Qijialing Village, Tongji New District, Jimo City, Qingdao

Non-woven fabric production line, non-woven fabric production line, non-woven fabric industry, Qingdao Runjuxiang Machinery Co., Ltd., melt-blown nonwoven fabric

Nonwovens industry:

Nonwoven fabrics are important raw materials for industrial textiles and are widely used in medical and health, filtration and separation, geotechnical and construction, and transportation. Due to its special functional structure and efficient production process, the non-woven fabric is very cost-effective and has a wide range of applications. Driven by continued growth in demand in recent years, global nonwovens production and consumption have maintained a relatively high growth rate. In 2016, despite the complicated domestic and international environment, China's non-woven fabric industry continued to maintain its growth momentum, and its economic benefits continued to improve.

produce

According to the statistics of the association, the output of China's non-woven fabrics reached 5.263 million tons in 2016, an increase of 8.5% year-on-year. Although the growth rate has declined compared with 2015, it is still in the high-speed growth range. According to the region, Shandong is the province with the largest output of non-woven fabrics in China. In 2016, the output of enterprises above designated size reached 947,000 tons. The output of non-woven fabrics in Shandong Province increased rapidly, on the one hand due to its geotechnical and waterproof coiled fabrics. In terms of rapid investment, the production capacity has expanded significantly. On the other hand, many traditional textile enterprises in Shandong have transformed into the field of non-woven fabrics. The investment intensity is relatively large, the equipment is advanced, and the single-line production capacity is relatively large. The output of Guangdong and Jiangxi increased by about 10%, while the output of non-woven fabrics in Zhejiang, Fujian and Anhui provinces increased by about 15%. China's non-woven fabric production is mainly concentrated in the eastern coastal areas, accounting for 70.2% of the country's output, and still maintains rapid growth; in the central and western regions, Hubei Province, due to the development of disposable medical and textile industry, its non-woven fabrics The output reached 408,000 tons. Although the output in Henan and Sichuan was not large, it maintained a high growth rate.

investment

The demand for nonwovens is diverse and growing rapidly, so the industry's investment is very active, but it also shows a certain periodicity. In 2016, China's non-woven fabric industry actually completed fixed assets investment of 30.622 billion yuan, an increase of 13.87% year-on-year. This indicator's growth rate in 2014 was 44.2%, which was the highest point in recent years. Since the non-woven fabric production line takes about one year from the investment to the final realization, the industry needs time to digest the newly increased production capacity. Therefore, after the decline in investment growth in 2015, the investment growth rate in 2016 has risen, and it is expected that 2017 The investment growth rate of the non-woven fabric industry will continue to improve.

According to the statistics of some equipment manufacturers in the association, in 2016, China's industrial textile industry added 152 new needle-punching production lines, 33 new spunlace production lines, and 19 hot-air and hot-rolling production lines, reflecting the industry's investment. A higher heat.

Economic benefit

In recent years, the nonwovens industry has maintained a good profitability. According to the National Bureau of Statistics, in 2016, the main business income and profit of non-woven fabrics above designated size were 155.84 billion yuan and 9.93 billion yuan, respectively, up 7.67% and 8.23% year-on-year, and the profit rate was 6.38%. The loss amount fell sharply by 43.32%, indicating that the industry's profitability has further improved. The improvement of the industry's profitability, on the one hand, benefited from the technological advancement of the industry and increased the technological added value of the products. On the other hand, the increase in the output of the main products of the enterprise and the decline in the inventory of finished products and the amount of accounts receivable made the production and operation of the enterprise be benign. The cycle has promoted the sustainable development of the industry.

In the past five years, the growth rate of the main business income of the non-woven fabric industry in China has undergone a major change. In 2016, it was 12 percentage points lower than that in 2012, while the output of the industry in the same period increased sharply. The main reason for the decline in the growth rate of the main business income was that the decline in the price of raw materials such as polypropylene chips and polyester staple fibers caused the decline in the price of raw materials, which hindered the increase in the sales price of non-woven products, and even declined to some extent.

international trade

In 2016, China exported 821,000 tons of non-woven fabrics, amounting to 2.52 billion US dollars, up 12.25% and 1.49% respectively. In the context of the overall decline in the export of industrial textiles, the export of non-woven fabrics still maintained a good momentum. The quantity is the main factor driving the growth of China's non-woven fabric exports. From 2012 to 2016, the export of non-woven fabrics by weight increased by 14.08% annually, which is higher than the average annual growth rate of non-woven fabric exports. In terms of export prices, the export unit price of non-woven fabrics in 2012 and 2013 maintained a low growth rate, which began to decline after 2014. In 2016, it dropped by nearly 10%. In the five years, the export price decreased by 2.2% annually.

The non-woven fabrics exported from China are mainly composed of staple fibers, and the weight of staple fiber nonwovens accounts for 51.33% of the total. In 2016, the weight of spunmelted non-woven fabrics exported by China accounted for 48.67% of the total amount, accounting for 43.7% of the total, which was an increase compared with 2015. From the processing level, the non-woven fabric treated by impregnation accounted for 44.31% of the export value, and its unit price was 41.82% higher than that of other untreated nonwoven fabrics. It can be seen that the finishing of the non-woven fabric is to increase the added value of the product. One of the important ways.

From the market point of view, Asia is still the largest export market for non-woven fabrics in China, with exports increasing by 2.49% year-on-year and accounting for more than 60% of total non-woven fabric exports. The EU and North America are another important market for nonwovens in China. Compared with last year, non-woven fabrics exported to the EU increased by 2.61% year-on-year; exports to North America decreased by 3.9% year-on-year due to the decline in exports from the US market. .

Non-woven fabric exports to Latin America and Oceania increased by 5.45% and 18.82% respectively year-on-year; Africa was affected by the global economic downturn in 2016, and its development momentum was hindered. China's exports of its non-woven fabrics decreased by 18.96% year-on-year, but The overall development potential of the African market is still sufficient. Domestic non-woven fabric products have a good cost performance, and there will be better development prospects in the African market in the future.

The development of the nonwovens industry in China is not long, but the speed is very fast, and it can be said that it has experienced explosive growth. In 2001, the output of China's non-woven fabrics was only 569,000 tons, only 10.8% of the output in 2016. In the past 15 years, the annual growth rate of China's non-woven fabrics reached 16%; from 2000 to 2015, China's non-woven fabrics. Exports increased from 34,000 tons to 732,000 tons, and exports increased from 94 million US dollars to 2.49 billion US dollars, with an average annual growth rate of 22.58% and 24.4%, and the share of global trade increased from 2.1% to 17.6%. After years of development, China has become the world's largest producer, consumer and trading country of nonwovens.

The following is the production process and principle of the melt-blown nonwoven technology introduced by Run Juxiang Xiaobian. The melting process has been analyzed in recent years from the aspects of meltblown nonwoven production technology, meltblown new materials and meltblown nonwoven products. The development of spray non-woven technology.

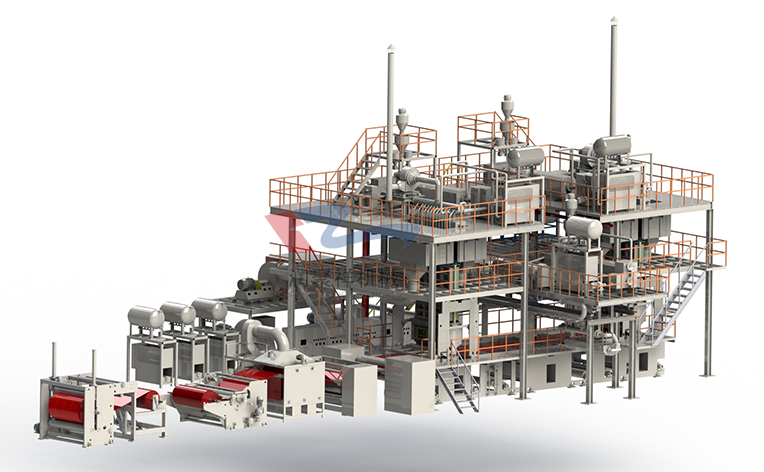

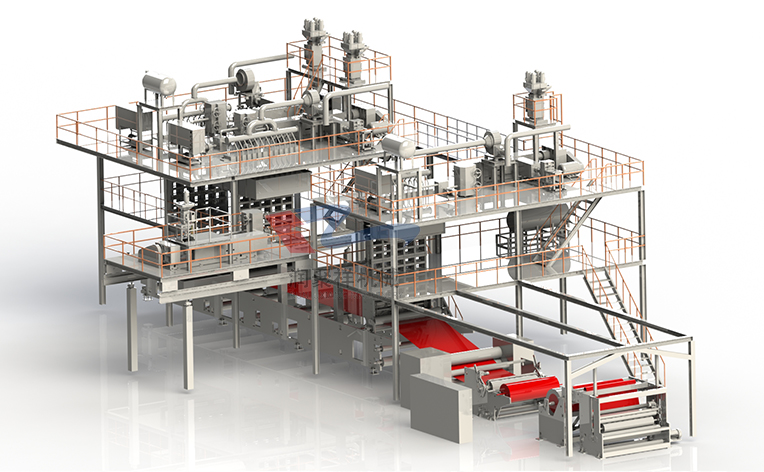

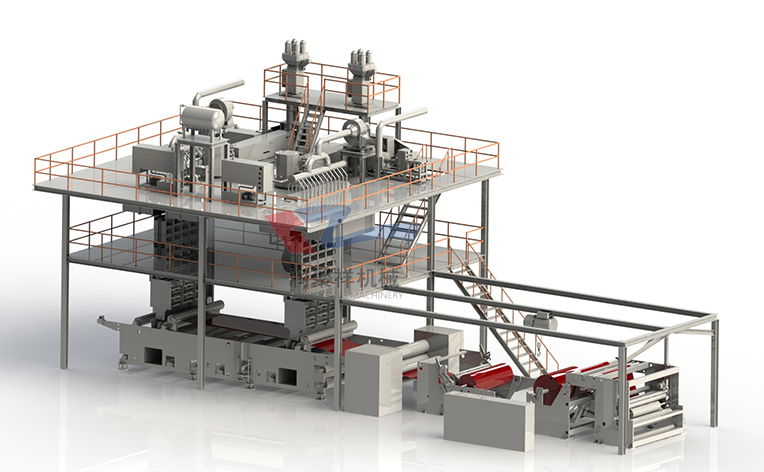

M meltblown nonwoven production line (single die head) of Qingdao Runjuxiang Machinery Co., Ltd.

The maximum production speed can reach 100 m / min.

4.2 meter production line, technical parameters

The weight range is 8-80 g/m2. The maximum speed is 100 m/min. The production capacity is 2300 tons/year.

3.2 meter production line, technical parameters

The weight range is 8-80 g/m2. The maximum speed is 100 m/min. The production capacity is 1700 tons/year.

2.4 meter production line, technical parameters

The weight range is 8-80 g/m2. The maximum speed is 100 m/min. The production capacity is 1300 tons/year.

1.6 meter production line, technical parameters

The weight range is 8-80 g/m2. The maximum speed is 100 m/min. The production capacity is 850 tons/year.

Qingdao Runjuxiang Machinery Co., Ltd. is a professional manufacturer of meltblown nonwovens. Qingdao Runjuxiang Machinery Co., Ltd. was established in Wenzhou in 1998. With the development of the company and the expansion of its business, it moved to Qingdao in 2008 and established Qingdao Runjuxiang Machinery Co., Ltd. Up to now, only more than 200 sets of machining and manufacturing equipment, and equipped with professional testing equipment, have produced more than 200 production lines of polypropylene spunbonded non-woven fabrics.

Qingdao Runjuxiang Machinery Co., Ltd. has established a perfect after-sales service system, which eliminates customers' worries, quick response, one-stop service, and aims to “satisfy customer needs”.

Qingdao Runjuxiang Machinery Co., Ltd. was established in Wenzhou in 1998. With the development of the company and the expansion of its business, it moved to Qingdao in 2008 and established Qingdao Runjuxiang Machinery Co., Ltd. Up to now, only more than 200 sets of machining and manufacturing equipment, and equipped with professional testing equipment, have produced more than 200 production lines of polypropylene spunbonded non-woven fabrics.

If you would like to know more about our company, please contact: Mr. Gu 0315-5117262 Website: http://www.qdrunjuxiang.com

- Non-woven equipment manufacturer

- Future textile industry status a

- Main technical indicators of non

- Textile industry operation "stab

- Introduction of non-woven produc

- Textile industry attitude back t

- Non-woven equipment is a kind of

- Textile industry transition crit

- Non-woven equipment supplier rec

- Textile industry to maintain rap

- About RunJuXiang

- Company Profile

- Company Culture

- Non-woven production line

- Spunbond nonwoven production line

- Two-component Bi-Co

- Spun melted nonwoven production line

- Equipment Accessories

- Meltblown nonwoven production line

- Non-woven products

- News Center

- Company News

- Show Information

- Contact Us

- Contact RunJuXiang

- Online Message